Stainless hlau I screws nyob rau hauv tus txheej txheem ntawmElectrolytic Polishing, electrolysis lub sijhawm thiab ntsev tshuaj tsuag lub sijhawm yog kev sib raug zoo, ces yuav muaj kev sib raug zoo ntawm lawv li cas?

Cov khoom siv uas peb siv hauv qhov kev sim no yog 201 stainless hlau screws, tab sis cov khoom ua haujlwm tsis zoo, paub tias yuav tsum tau dej hauv huab cua tom qab 30 feeb ntawm kev kis tau xeb qhov xwm txheej loj heev.

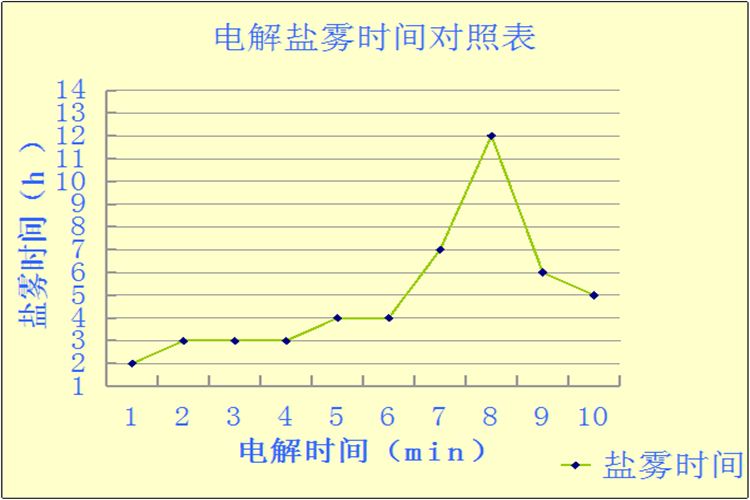

Qhov kev sim tshuaj potion yog nrog stainless hlau electrolytic polishing kev tswj hwm ntawm 9,2 volts yog unf electrolytic mus kuaj lub sijhawm thiab tiv thaiv xeb.

Cov duab ntawmStainless hlau electrolytic Polishing tovTom qab electrolysis:

Tom qab cov electrolysis tau ua tiav, 10 khob tau soaked nyob rau hauv 5% brine, thiab cov txiaj ntsig tau muaj raws li hauv qab no:

Cov duab tom qab soaking hauv cov ntsev dej:

Cov lus xaus nram qab no tau kos los ntawm qhov kev sim no:

1. Lub sijhawm ntev dua lub sijhawm hluav taws xob, qhov ntau dua cov npoo ntawm lub workpiece.

2. Tom qab electrolysis, cov cuab yeej antator yog hloov kho.

3. Nws tsis yog qhov xwm txheej ntawd ntev dua lub sijhawm hluav taws xob, ntev ntev dua cov kev ua haujlwm antir.

Lub Sijhawm Post: Lub Tsib Hlis-09-2024