Daim iav tiav electrolytic polishing tus neeg sawv cev

Silane coupling cov neeg sawv cev rau txhuas

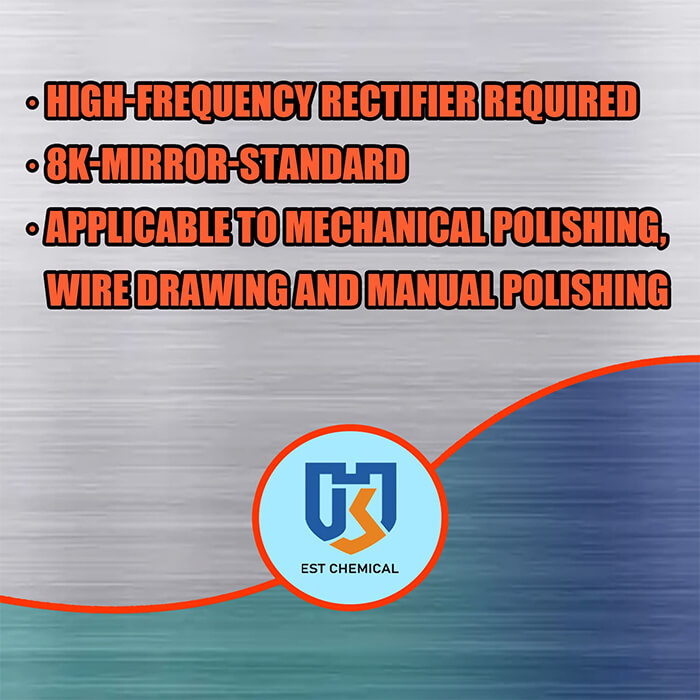

Cov lus qhia

| Khoom Npe: Stainless Hlau Iav Ntais | Packing specs: 25kg / nruas |

| PH tus nqi: <1 | TSHWJ XEEB LUB HLOB: 1.72 + 0.05 |

| Dilution piv: undeluted daws | Solubility hauv dej: tag nrho cov yaj |

| Cia: Qhov chaw tso pa thiab qhuav | Txee Lub Neej: 12 lub hlis |

Nta

| Yam: | Daim iav tiav electrolytic polishing tus neeg sawv cev |

| Tus Qauv Zauv: | KM0304 |

| Hom Lub Npe: | Yog tshuaj lom neeg |

| Qhov chaw ntawm keeb kwm: | Guangdong, Suav |

| Zog: | Pob tshab tsis muaj kua |

| Cov Lus Qhia Tshwj Xeeb: | 25kg / thooj |

| Hom kev ua haujlwm: | Kev Ntsuas Hluav Taws Xob Hluav Taws Xob |

| Lub sijhawm raus dej kawm: | 2 ~ 5 mins |

| Kev Ua Haujlwm Kub: | 60 ~ 80 ℃ |

| Tshuaj phom sij: | No |

| Tus Qauv Txheem: | Muaj Qeb |

Cov FAQ

Q1: Koj lub tuam txhab Bussin yog dab tsi?

A1: Muaj cov pab pawg siv tshuaj, nrhiav tau nyob rau xyoo 2008 tsuas yog koom nrog kev tshawb fawb, kev tsim khoom thiab muag khoom ntawm tus neeg saib xyuas tsis muaj xeb thiab cov kua hluav taws xob roj. Peb lub hom phiaj los muab cov kev pabcuam zoo thiab raug nqi rau cov khoom lag luam thoob ntiaj teb.

Q2: Vim li cas thiaj xaiv peb?

A2: Muaj cov pab pawg siv tshuaj lom neeg tau tsom mus rau hauv kev lag luam rau ntau tshaj 10 xyoo. Peb lub tuam txhab yog coj lub ntiaj teb ntawm cov hlau passivation, xeb remover thiab electrolytic polishing kua nrog kev tshawb fawb loj & chaw tsim loj. Peb muab cov khoom lag luam ib puag ncig nrog cov txheej txheem kev ua haujlwm yooj yim thiab lav tau tom qab muag rau lub ntiaj teb.

Q3: Koj tau lav qhov zoo li cas?

A3: Nco ntsoov muab cov qauv ua ntej tsim ua ntej pawg ntau lawm thiab kev tshuaj xyuas zaum kawg ua ntej cov zaub mov xa tuaj.

Q4: Koj tuaj yeem muab dab tsi pab?

A4: Kev Ua Haujlwm Kev Ua Haujlwm thiab 7/24 tom qab muag cov kev pabcuam.

Q: electrolytic polishing muaj dab tsi zoo rau cov neeg kho tshuab polishing,

A: tuaj yeem yog pawg ntau lawm, txawv ntawm cov khoom siv kho tshuab ua polishing, tsuas yog ua polishing ib leeg. Lub sijhawm ua haujlwm yog luv luv, kev ua haujlwm siab ntau. Tus nqi qis. Tom qab electrolysis, qhov chaw av yooj yim los ntxuav, nws sib txawv los ntawm cov khoom siv tshuab ua kom zoo nkauj, yuav muaj ib txheej ntawm cov khoom sab, nws tsis yooj yim ntxuav. Yuav tuaj yeem ua tiav daim iav Lus Cim Cov nyhuv lus, thiab tsim corrosion tsis passivation membrane. Tuaj yeem txhim kho kev tiv thaiv kev tiv thaiv xeb ntawm cov khoom