Color Preservation Pickling Cleaning Fluid For Stainless Steel

Silane Coupling Agents For Aluminum

Instructions

|

Product Name : Stainless steel color |

Packing Specs : 25KG/Drum |

|

PHValue : <1 |

Specific Gravity : 1.11土0.05 |

|

Dilution Ratio : Undeluted solution |

Solubility in water : All dissolved |

|

Storage : Ventilated and dry place |

Shelf Life: 12 months |

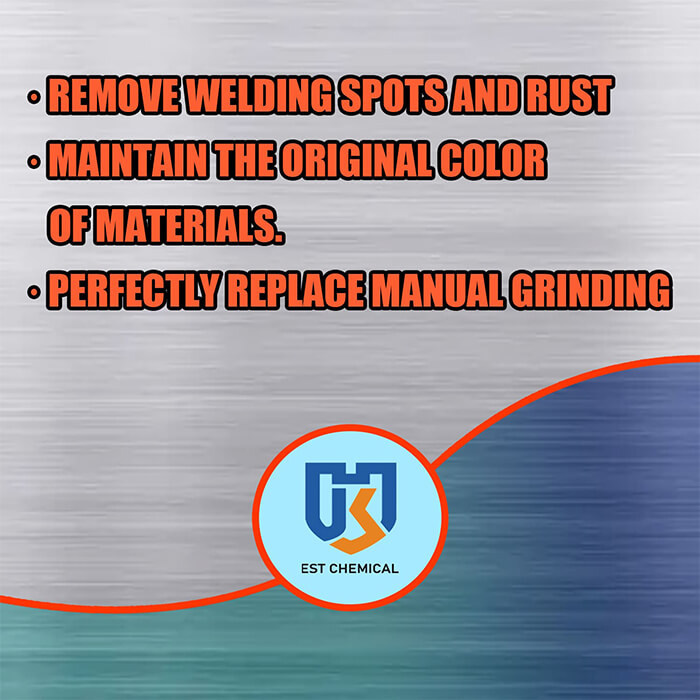

Features

|

Item: |

Color Preservation Pickling Cleaning Fluid For Stainless Steel |

|

Model Number: |

KM0227 |

|

Brand Name: |

EST Chemical Group |

|

Place of Origin: |

Guangdong, China |

|

Appearance: |

Transparent colorless liquid |

|

Specification: |

25Kg/Piece |

|

Mode of Operation: |

Soak |

|

Immersion Time: |

3~8 mins |

|

Operating Temperature: |

Normal atmospheric temperature |

|

Hazardous Chemicals: |

No |

|

Grade Standard: |

Industrial grade |

FAQ

Q1: What’s your company’s core bussiness?

A1: EST Chemical Group, founded in 2008, is a manufacturing enterprise mainly engaged in the research, manufacture and sales of rust remover, passivation agent and electrolytic polishing liquid. We aim to provide better service and cost-effective products to global cooperative enterprises.

Q2:what industry can be adopt passivation craft?

A2: As long as the hardware industry, will be to use our products,like home appliance, nuclear power, cutting tool, tableware, screw fasteners, medical equipment, shipping and other industries.

Q3:why the stainless steel products need passivation?

A3:With the development of economy, more and more products are exported to Europe and the United States,But because of need to travel through the sea, abominable(terrible/awful) environment is easy to cause the products rust,In order to ensure the product does not rust on the sea, so must need to do a passivation treatment, in order to enhance product antirust corrosion resistance

Q4:The products need to clean the surface oil and dirt before passivation?

A4:Because the product in the process of machining( wire drawing, polishing, etc.),some oil and dirt adhere on the products surface. Must clean this smudginess before passivation, because of this smudginess in the product surface will be prevents passivation liquid contact reaction, and will be affect the appearance of the passivation effect and product quality.